Item number: 60151

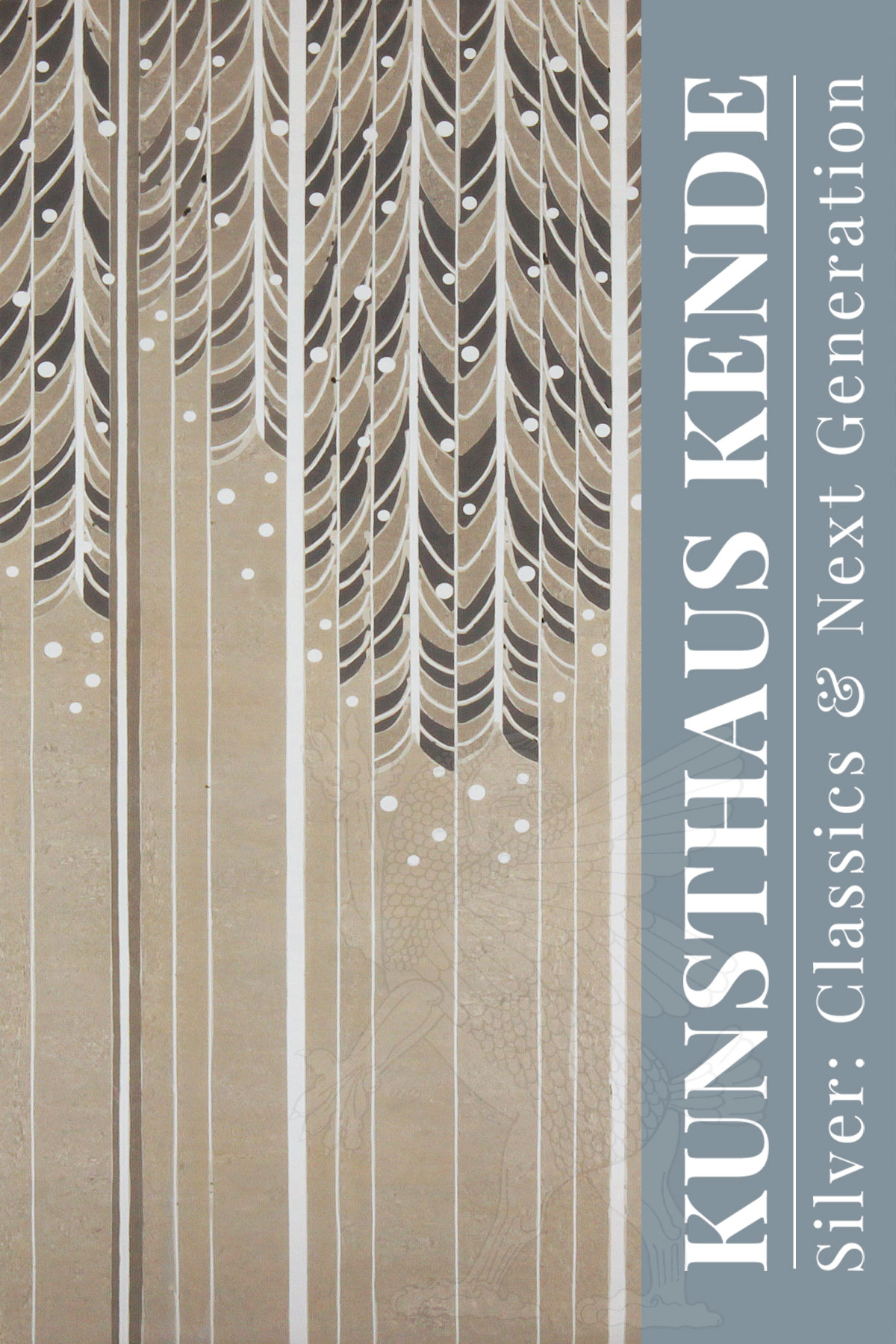

An exceptional Hagiawase jardinière,

Silver, Copper, Shakudo, Shibuichi,

Yamaguchi 2014 by Yoshiko Okamoto

Navette-shaped form, the wall subtly tapering towards the ends, the base sloping upwards analogous to the ends. The upper rim terminated by a square moulding. The body adorned with an abstract frieze of foliage in alternating colours at alternating heights, which is decoratively subdivided by subtle linear decoration. The pattern has been made in the traditional Japanese hagiawase technique.

A masterfully crafted jardinière or flower planter of outstanding quality, brilliant finesse and unobtrusive elegance.

26.8 cm / 10.55″ length, 8.4 cm / 3.30″ width, 11.4 cm / 4.48″ height

The Japanese artist-silversmith Yoshiko Okamoto

The Japanese artist-silversmith and designer Yoshiko Okamoto (born 1976 in Yamaguchi) began as an illustration artist in Yamaguchi Prefecture, her favourite themes being the four seasons and depictions of the beauty of Japanese nature. She first took part in arts and crafts courses under the guidance of metal artist and living national treasure Akira Yamamoto (also from Yamaguchi Prefecture) while she was still at school, which awakened her interest in traditional Japanese metalworking techniques. After leaving school, she became a master student of Yamamoto and learnt from him the special techniques of hagiawase (hot soldering with metal forging) and kiribame-zogan (heat-welding of cut-out inlays). Her preferred subject has remained the same throughout her artistic career: the endless story of nature, woven from the four seasons, into which she incorporates her artistic perspectives, represented by a masterful colour gradation of several layers of metal.

The traditional Japanese Hagiawase forging technique

Hagiawase (Japanese for ‘brazing’) is, to put it simply, a technique in which different types of metal sheets are joined together. This technique makes it possible to create metalwork with striped or patchwork patterns. After joining, the artist shapes the metal with a hammer.

The work often consists of silver (white), different types of shibuichi (an alloy of copper and silver that appears grey at the end of the work) and shakudo (an alloy of copper and gold – black at the end). The surface of shibuichi becomes light grey when silver is added, the addition of copper makes the colour appear progressively darker depending on the quantity, and the addition of gold makes it dark grey.

These metal alloy plates are cut with a fine saw to produce the intended pattern. These plates are joined together with silver and then melted with a gas burner to bond the pieces together. Alternatively, hotter flames are used to bond the different metals together directly. As it is not possible to produce the pattern exactly as designed each time, Yoshiko Okamoto performs this hagiawase process several times until she has the desired number of patterns.

When the pattern plates are finished, she only grinds the inside to smooth out the unevenness caused by the soldering. She then begins to mould the metal by driving it with a hammer. Once the basic shape has been created, the pattern of white dots is incorporated: for this purpose she drills holes with a drill of maximum 1 mm diameter, inserts a short-cut round wire made of pure silver into the hole and fixes the protruding part of the silver by hammering. The protruding part is then removed subtractively to bring it level with the surface. This technique is known in Japanese as Kiribame-zogan.

The surface is then sanded by hand using coarser abrasive media, the grain of which becomes progressively finer during the sanding process until the metal has a high lustre at the end.

Once all the sections have been completed, the inner surface of the work is sanded again with coarse sandpaper and the individual parts are harmonised to each other to their edges. The metal plates are then assembled to form the three-dimensional workpiece, fixed together with wire and the segments soldered together. Finally, the surface is preserved using the traditional Japanese patination technique Niiro.